NEST – A Showcase for Sustainable Construction and Building Technologies

NEST is a dynamic, modular research and demonstration platform for advanced and innovative building technologies in the heart of the Empa-Eawag campus in Dübendorf, Switzerland.

As a “future living and working lab”, NEST consists of a central backbone and a basic grid to accommodate exchangeable living and office modules, allowing novel materials and components and innovative systems to be tested, demonstrated and optimized under real-world conditions.

As partners of NEST, the institute of Technology in Architecture at the Swiss Federal Institute of Technology in Zurich (ETHZ), has joined forces with Supermanoeuvre (sM) and the architects ZJA in a collaborative effort to contribute to the future of construction by developing “HiLo”, a research & innovation unit for NEST in the domain of ultra-lightweight construction, which functions as a duplex penthouse for visitors to the faculty. Within the team, sM are the design architects of HiLo, while ZJA are partners for the design and development of HiLo’s thin-shell roof.

HiLo for NEST introduces the following key innovations:

Floor system innovation:

Introducing funicular vaulting as a floor system results in an extremely lightweight floor system with savings of more than 70% of weight compared to traditional concrete floor slabs. This also allows for a natural and efficient integration of services and low energy heating – and cooling systems, further saving significant floor height. The system is of a bespoke, modular and prefab nature, made possible through a robotically controlled, intelligent fabrication setup, resulting in lightweight elements that can very quickly be assembled on site.

Integrated roof innovation:

The roof system will be very lightweight and extremely thin, less than 70mm, including both a thin shell structure and building systems. The large surface area of the shell is used for heat transfer into the space using a hydronic low temperature heating and cooling system. Custom, doubly curved vacuum insulation will be used to achieve a low thermal transmittance at very small thickness. On top, optimally distributed, high-efficiency thin-film photovoltaic cells are used for solar energy generation.

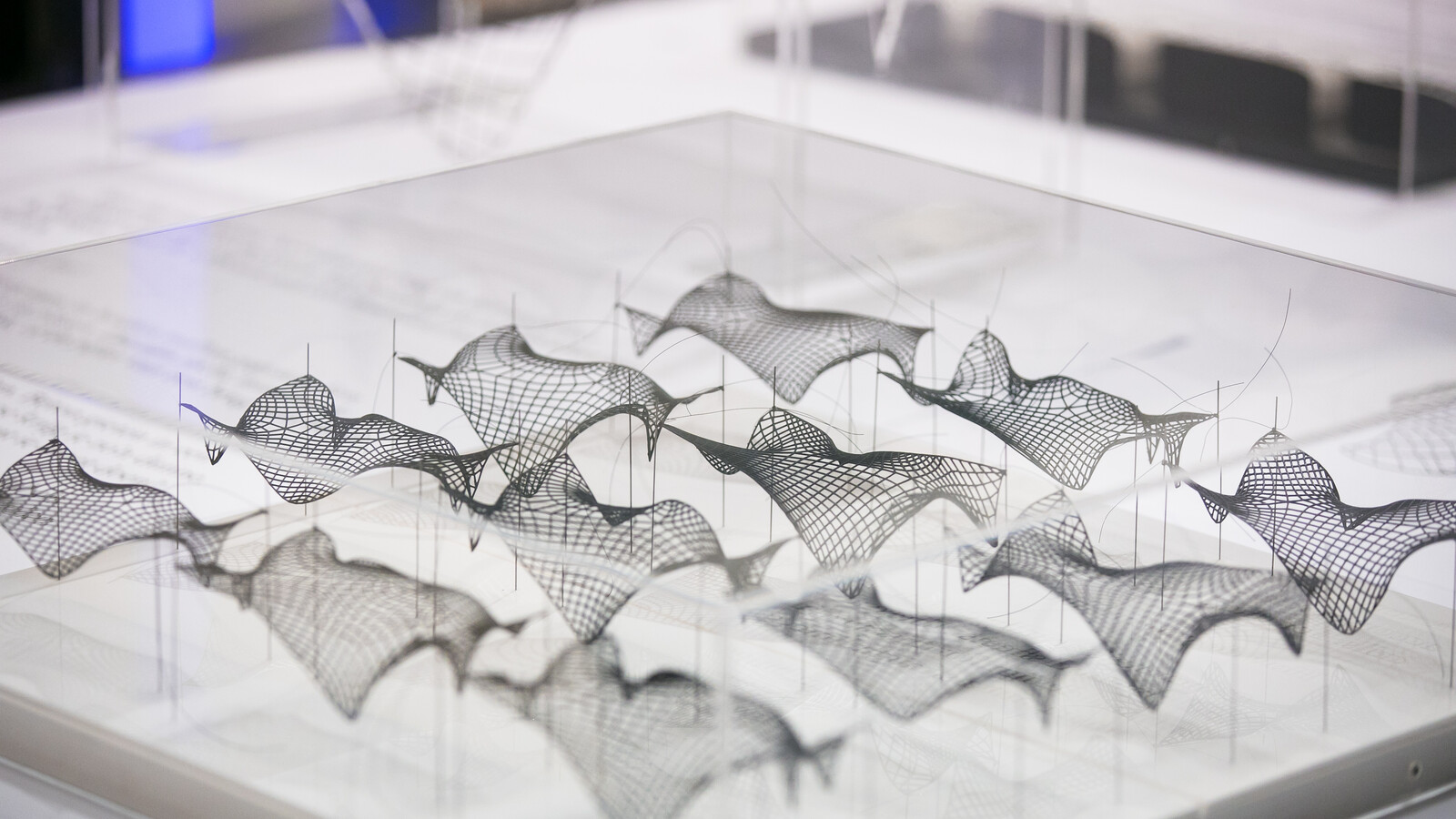

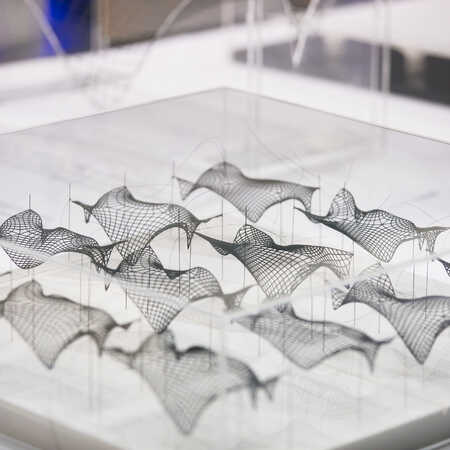

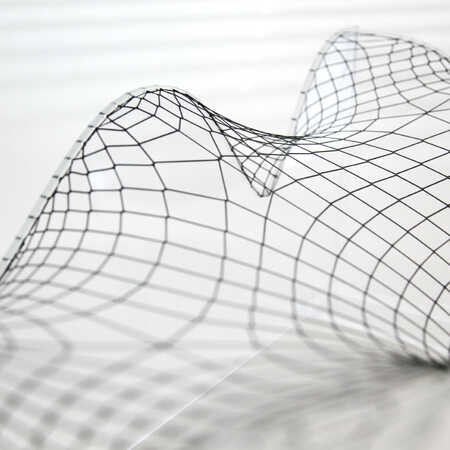

Construction innovation:

A highly efficient, reusable and lightweight mixed cable-net and fabric formwork system allows the reintroduction of the efficient, doubly curved thin shell roof structures without the typically associated high labor and resource investments. The formwork system offers a degree of control over the shape such that it can be easily optimized for improved structural behavior and other criteria compared to traditional geometries.

Adaptive façade innovation:

Employing novel soft pneumatic actuators, the adaptive solar envelope consists of static and movable modular elements that are mounted curtain-like in front of the façade. The elements provide solar energy generation, shading and control the visibility and transparency of the façade. In correspondence to changes of the outside environment and demands of the interior, the elements can rotate to provide the desired functionality. The different modes of the modules are controlled based on sensor as well as on occupant input. Adaptive learning algorithms facilitate the continuous improvement of the behavior and thus the adaption of the modules to their users and environments.

Building systems innovation:

The proposed energy concept of HiLo targets zero emissions in operation, high efficiency and full integration of system components into structural elements, leveraging their specific attributes. All the systems for interior climatization as well as energy harvesting are controlled by a building automation system to optimally balance the dynamics and user preferences. Novel user-centered approaches are applied that use methods of machine learning and adaptation under real-life operational conditions.

project: 736